Manufacturing mold is a complex process that requires attention to detail and careful consideration of several key factors.

Here are 10 things that should be noticed when manufacturing a mold:

Material selection:

The choice of material used to create the mold can have a significant impact on its performance and longevity. It is important to select a material that is durable, corrosion-resistant, and able to withstand the high temperatures and pressures of the injection molding process.

Mold design:

The design of the mold is critical in ensuring that the final product meets the required specifications. The mold should be designed to produce parts with the desired shape, size, and features, while minimizing defects such as warpage and sink marks.

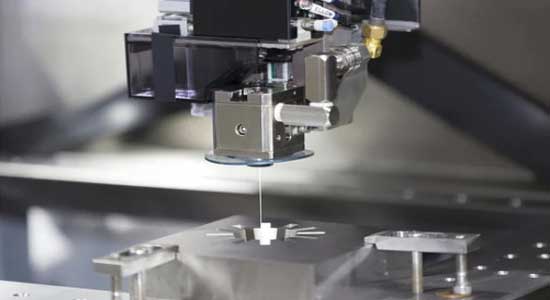

Surface finish:

The surface finish of the mold is important in ensuring that the final product has a smooth and consistent appearance. The mold should be polished and finished to a high standard, with no visible scratches or imperfections.

Cooling system:

The cooling system is critical in ensuring that the mold can be used repeatedly without overheating. The cooling channels should be designed to provide efficient and even cooling to the mold, reducing cycle times and improving part quality.

Ejection system:

The ejection system is used to remove the part from the mold cavity once it has been formed. The ejection system should be designed to minimize the risk of part damage or deformation, while also allowing for efficient and consistent ejection.

Venting:

Venting is used to allow air to escape from the mold cavity during the injection molding process. Proper venting is essential in preventing defects such as gas traps, voids, and burns.

Gate design:

The gate is the point at which the molten plastic enters the mold cavity. The gate design should be optimized to provide efficient filling and minimize the risk of defects such as flow marks, flash, and knit lines.

Runner system:

The runner system is used to transport the molten plastic from the injection molding machine to the mold cavity. The runner system should be designed to minimize waste and reduce cycle times, while also ensuring consistent and efficient filling of the mold.

Mold maintenance:

Regular maintenance of the mold is essential in ensuring that it continues to perform at a high level over time. The mold should be cleaned and inspected regularly, with any wear or damage repaired as necessary.

Quality control:

Quality control measures should be in place throughout the mold manufacturing process to ensure that the final product meets the required specifications. This may include dimensional inspections, material testing, and visual inspections to detect defects or imperfections.

XIAMEN MODERN MOULDS&TOOLS CO., LTD

Expect to start the product development journey together with you

Call Us

+86 13599537590