Injection Molding Molds Manufacturing

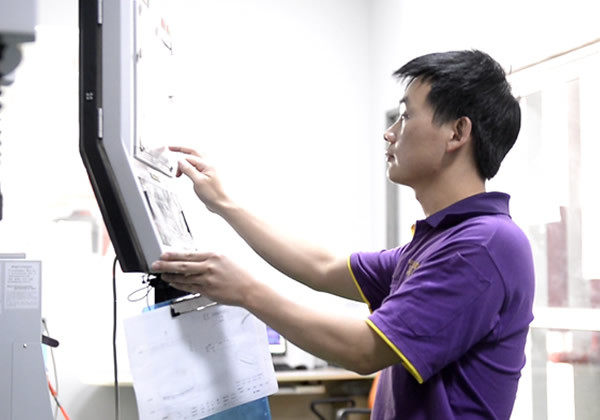

MMT mold production experience comes from European partners who possesses 45 years of professional manufacturing experience. There is a complete and strict standard process from mold design, processing to acceptance. After 16 years of close cooperation with partners, we have gathered rich experience in manufacturing HASCO and DME molds, while adopting the automation and intelligence of mold manufacturing. We ensure high-quality products and services based on the advanced equipment, complete project management flow and rich experienced staffs

Mold Making Process

Materials for your injection mold tools are high-quality P20, 718H, 838H, H13 tool steels etc. Rubber molds making supplies use imported multi-axis CNC and EDM machines to create complex pattern with various surface finishes like gloss, matte or special textures like wooden finish, leather grains, chemical etching etc.

Die Casting Materials can be aluminum, stainless steel, zinc aluminum alloy etc. Various surface treatment are available like chrome plating, zinc plating, nick plating, powder coating, e-coating, dip coating, mirror polishing etc.

MMT provides a dedicated project manager and engineer for your injection molding production.

Mold Making Tolerances

Unless otherwise specified by you, our standard tolerances conform to DIN-2768-1-fine.You are welcome to mark the tolerances for each tool parts on 3D drawing.

For best mold making service, contact us now!