QUALITY INSPECTION

After OEM/ODM die and mould manufacturer finished molding,We provide post molding service like ultrasonic welding, silk printing, surface finish service.

Making high-quality products requires completed quality management system through full inspection process.

At MMT, we have completed quality inspection system and related rules, We make sure every project follows these steps for quality assurance:

1. Quality Control Solution before Molds/Tools Manufacturing

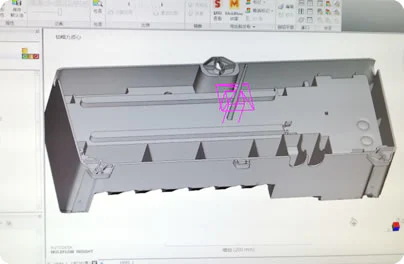

• DFM: We have a professional mold engineering team, most of them have over 10 years' mold manufacturing experience. For every project, our engineering team will make Design for manufacturing review before mold manufacturing.

• Moldflow Analysis: We use Moldflow software to make plastic injection and compression mold simulation, which can improve plastic part design, injection mold design, manufacturing processes.

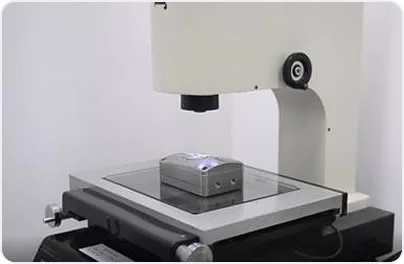

2. Quality Control Solution during Molds/Tools Manufacturing

Hardness testing on steels through all necessary manufacturing stages.

• Material

• Electrode Inspection prior to EDM.

• Core and Cavity steel size inspection

• Working instruction for each mold part

• Mold fitting before injection and related reports

• Inspection instruction for each component

• All movable parts should be pushed by fingers to make sure the flexibility.

• 500 shots of dry cycle required before packing/delivery

3. Electronics and assembly quality control

Working instruction for each component

• Quality Inspection on incoming materials like plastic resin, pigments, colorants

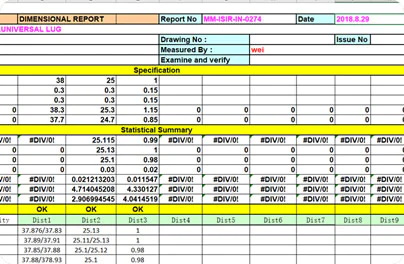

• First article and in-process inspection

• Final inspection and testing with reports as required

• Full FAIR in line to aerospace requirements in AS9100

4. Electronics and assembly quality control

Constant temperature and humidity storage room used to stock key electronic components.

• ESD test for workers before PCB assembling/inspection every day.

• Anti-electrostatic board and gloves used during electronic components assembling and inspection

• Golden samples signed by customers

• Specification checking on all electronic components

5. ISO Certified

We are proud to be fully certified and compliant with ISO 9001:2008 and we will apply for SA900 certification in 2020 to fulfill aerospace industry quality standard.