What can MMT do on Design Support?

MMT offers PCB design, 3D design and mould design.

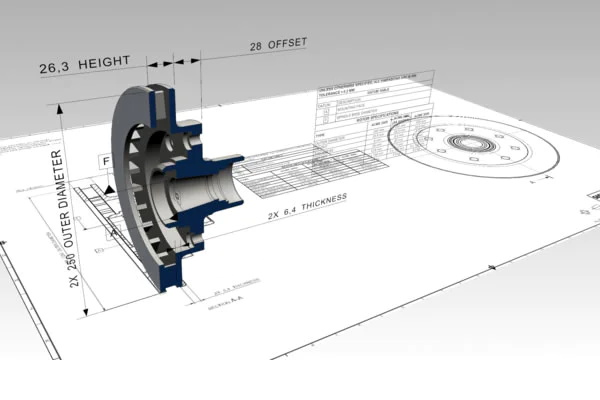

1. 3D drawing analysis: Our mechanical and mould engineers review your 3D drawing and offer professional advices to suit mould tool.

2. PCB design: We have professional electronics engineers to custom injection molding design PCB board and programme software and firmware.

Upon receipt of your ID, 3D drawing, sample or even just conception idea, we would like to discuss more details to make your products outstanding.